Case study: Conoco Phillips

Replacement of floor and complete floating roof

This project took place at the Conoco Phillips tank farm situated at Tetney Lock. The tank measured 51.8 meters in diameter and the tank circumference was 162.8 metres.

The project consisted of the removal of the existing floating roof and tank floor to scrap, design, fabrication and installation of a new floor, and floating roof which included a ring of pontoons and a centre deck.

The existing rolling ladder was to be refurbished at our workshops in Ellesmere port then shipped back to site for reinstallation onto a newly fabricated track.

In addition to the above, a new roof seal and foam dam was installed to the floating roof and the tank was installed with foam pourers and associated pipe work.

All of the roof support legs were replaced as were the vacuum breakers and the centre roof sump and roof drain. The pontoons came complete with inspection hatches.

The completed floating roof complete with the fully refurbished rolling ladder and track. The photo also shows the adjustable roof legs and vac breakers as well as the yellow foam pourers around the periphery.

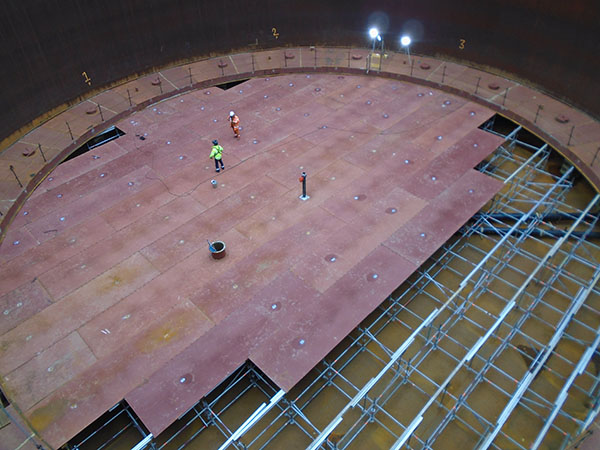

Installation of the new floor in preparation for welding.

The construction of the pontoons at our workshops in Ellesmere Port, Wirral. The pontoons were designed in house, each was constructed to mate up with the adjacent pontoon and shipped to site.

The installation of the pontoons progressing around the tank. The final pontoon was designed and fabricated to allow an installation tolerance of 30mm. When installed, the final pontoon fitted perfectly.

Contact us to find out how we can help you.